As electronics continue to shrink in size and grow in complexity, manufacturers are turning to insert molding to produce compact, durable, and reliable components. This process—where metal inserts such as pins, terminals, or shields are placed into a mold and encapsulated with plastic—has become a critical solution for modern electronic assemblies. And when it comes to high-precision, high-volume insert molding at competitive pricing, china mold manufacturers are leading the charge.

From connectors and sensor housings to EMI shielding and embedded circuitry, insert molding is helping electronics manufacturers reduce assembly steps, improve part integrity, and streamline production timelines. Here’s how China’s mold makers are pushing innovation in this space—and why electronics OEMs around the world are taking notice.

The Role of Insert Molding in Electronics

Insert molding allows engineers to create hybrid components that combine the strength, conductivity, or shielding properties of metal with the insulation, flexibility, or form factor benefits of plastic. This integration is especially valuable in electronics, where even a single connection failure can compromise device functionality.

Common applications include:

- USB and charging connectors

- Switch housings with integrated terminals

- PCB-mounted components

- Heat-sink-integrated parts

- RF and EMI-shielded casings

By embedding the metal during the molding process rather than assembling it afterward, manufacturers eliminate extra steps like soldering, bonding, or mechanical fastening. This reduces labor costs, minimizes tolerance stack-up, and improves consistency across high volumes. It also improves part reliability, which is critical for high-performance or safety-sensitive electronics used in automotive, medical, and industrial systems.

Why China Leads in Insert Molding for Electronics

China’s tooling and molding ecosystem has evolved rapidly over the last decade. What was once a low-cost outsourcing destination is now a global hub for innovation and precision—especially in electronics-focused manufacturing. OEMs from North America, Europe, and Southeast Asia increasingly turn to Chinese suppliers not only for pricing but for their technical capability and production speed.

Here’s what sets leading China mold manufacturers apart:

1. Advanced Tooling Capabilities

Insert molding requires highly accurate molds to ensure metal parts are held in place and perfectly aligned during injection. Chinese mold shops increasingly offer multi-cavity tooling with tolerances down to microns, suited for intricate electronic components. Many use high-speed CNCs, EDM machining, and precision CMM inspection to achieve the necessary accuracy.

2. Integrated Design and Engineering Support

Many suppliers in China now provide design-for-manufacturability (DFM) consulting, helping OEMs adjust their designs to improve moldability and reduce failure risks. This is especially helpful when dealing with complex insert placement or tight design envelopes. Working with an experienced engineering team early in the process reduces rework and tooling changes later.

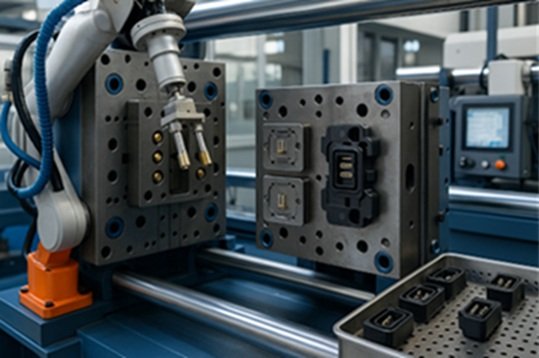

3. Automation and Scalability

Insert molding benefits greatly from automation—robots or pick-and-place systems are used to insert metal parts consistently into the mold before each cycle. Leading Chinese factories are investing in automated insert loading and in-mold inspection systems to support 24/7 high-volume production with minimal human error.

4. Material Versatility

Whether the project calls for high-temperature nylons, reinforced plastics, or conductive-grade polymers, molders in China can source and process a wide range of engineering materials suited for electronic use. They also understand the importance of UL-rated and RoHS-compliant materials in global electronics applications.

Innovation in Insert Molding Techniques

China-based manufacturers are also developing specialized insert molding approaches tailored for advanced electronics:

- Multi-shot insert molding for layered assemblies

- Soft-over-hard combinations for grips and insulation

- Co-molding with plated or surface-treated inserts

- High-precision micro-insert molding for miniature components

One emerging trend is insert molding for wearable electronics—smart rings, earbuds, and fitness trackers—where metal parts like charging contacts and antenna components are seamlessly overmolded for aesthetics and protection. Another is the use of insert molding to create water-resistant USB ports and connectors, commonly found in automotive and outdoor devices.

What to Look for in a Supplier

While capabilities in China have expanded, not all mold makers are equal. OEMs should look for partners with:

- Proven experience in electronics-related molding

- Robust quality management systems (e.g., ISO 9001, IATF 16949)

- Transparent communication and project tracking

- Samples of similar insert molding applications

- Ability to handle validation, testing, and compliance documentation

A good supplier will also be open to pilot runs, prototyping, and tooling modifications as your design matures.

Final Thoughts

Insert molding is more than just a process—it’s a strategic manufacturing approach that simplifies assembly, enhances product quality, and supports the miniaturization of modern electronics. As global demand for compact, multifunctional devices grows, so does the importance of efficient, high-precision manufacturing techniques.

By working with experienced China mold manufacturers, electronics companies can gain a competitive edge—not just in cost savings, but in product innovation, speed to market, and supply chain agility. Insert molding is no longer a niche capability—it’s a standard in advanced electronics manufacturing.

Refresh Date: August 22, 2025